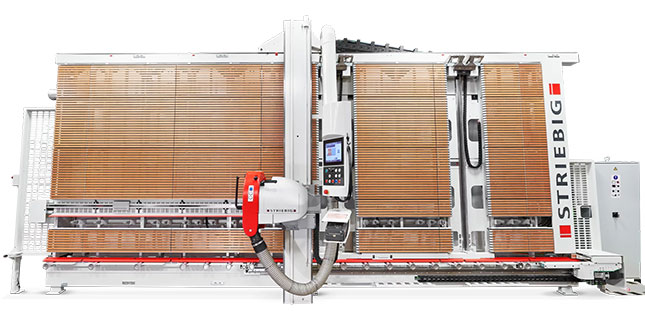

The Striebig 4D automated vertical panel saw represents a quantum leap forward in vertical panel saw technology. It can optimise and cut a full-sized panel without the operator needing to re-handle it once it has been loaded on to the machine’s bed, providing effortless, one-person operation.

Designed for businesses with high levels of sizing requirements, it’s the world’s first automated vertical panel saw to offer intelligent cut optimisation, for even the most complicated panel and strip cutting work. This ensures excellent levels of efficiency together with maximum material utilisation.

Each Striebig 4D automated vertical panel saw is tailor-made for a customer’s individual needs, following in-depth consultation sessions. Thorough customising is the order of the day with a virtually endless variety of options available – each designed to significantly improve the sizing capabilities in your business. Delivering a cutting range of 5300 x 2100mm, the Striebig 4D comes with the option to cut depths of 80, 105 and 130mm.

Once the panel is loaded, the Striebig 4D panel saw is effortless. The operator simply loads the panels, presses the start button, removes the finished work pieces and positions them ready for further processing operations. Data can be entered via the intuitive touch screen or the Striebig 4D can be connected to customers’ own optimisation software.

With the fully automatic panel lowering device PAV, the programmable panel feeder PPS and the equipment package Striebig ExpertCut 4D, the Striebig 4D offers unique equipment options.

The fully automatic panel lowering device ensures that the panel material passes through the machine smoothly and vertically. The PAV clamps are coated and designed for sensitive surfaces. The clamps hold panels weighing up to 130 kg per lowering device.

The fully automatic, programmable panel feeder ensures the horizontal transport of the workpiece.

With the equipment package Striebig ExpertCut 4D, the Striebig 4D offers intelligent and convenient cutting optimisation. The program facilitates an automatic cutting sequence with an optimum sawing procedure and the best possible material utilisation. This ensures consistency in the production process and allows the workpiece to be marked directly from the label printer.

| Weight of the saw | approx. 1.800 kg |

| Cutting depth | 80 mm *1 |

| Saw motor power | 5.5 kW (7.5 HP) |

| Saw blade diameter | 300 mm *2 |

| Saw blade bore | 30 mm *3 |

| Emission sound pressure level at the workplace LpA | 83 dB *4 |

| Saw blade speed | 4800 rpm |

| 1 extraction connection | ø 140 mm |

| Compressed air connection | 6-10 bar |

| Wattage (incl. PAV/PPS) | 9.1 kW |

| Mains connection | 3 x 400 V / 50 Hz |

At TM Machinery, we are committed to providing top-notch machinery solutions to meet your industrial needs. Whether you’re looking for cutting-edge equipment, maintenance services, or expert advice, we’re here to assist you every step of the way.

Whether you’re an existing customer seeking support or a potential client interested in exploring our products and services, we invite you to get in touch with us.

For more information on the Striebig 4D you can download the product brochure here.

T.M. Machinery supply high quality new and used industrial woodworking machinery including vertical panel saws, sliding table saws and dust extraction.

In addition to the products we supply, we also have a large team of engineers providing repair and maintenance services for a wide range of woodworking machinery.