Specialist security door manufacturer, Stafford Bridge Doors, has achieved greater all-round efficiency by replacing a sliding table saw with a Striebig Evolution vertical panel model.

As well as halving the time it takes to size a door, it’s delivering improved cutting accuracy and has brought about a switch to one-man operation.

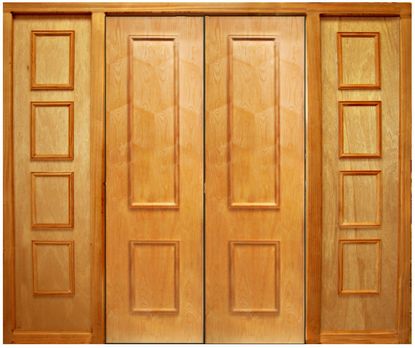

Stafford Bridge Doors, based in the village of Pavenham, near Bedford, produces bespoke high performance timber and steel composite security door sets. It was the first company to achieve certification to LPS 1175 Security Rating 3 with a timber core door, with higher ratings achieved for composite steel and timber cores.

It is the market leader in high performance door sets, together with a choice of locks and door furniture to provide the widest range of operational requirements. It has British and European certification providing assurance of protection against physical attack, ballistics, blast and fire, both individually and for combined requirements. It also provides a complete installation service.

Amongst its customers are Government departments including the MoD, major utilities, telecommunications companies, special hospitals and secure units, banks and buildings societies, with its doors in use around the world.

Striebig Evolution provides all round efficiencies

The Striebig Evolution 5216 has a maximum cut size of 4300 x 2160mm and a maximum cutting depth of 80mm.

It was bought as part of a £200,000 investment programme in new production equipment needed to cope with a rise in sales. This has also included a Homag Weeke CNC Venture CNC machining centre, a Weber sander and a Steton veneer press.

The saw is housed in a new door manufacturing unit and is cutting hardwood door cores, 55mm thick, generally 25% denser than normal hardwoods and weighing between 60 and 120 kg per leaf.

On arrival the cores are cut to size on the Striebig before being faced with plywood and laminates of steel, manganese steel and veneer facing. After being put through the press they go back on to the saw for a final trim, before being lipped.

Said the company’s technical director, Jim Russell: “When we took on the additional factory unit we decided to buy a vertical panel saw for improved use of space and better efficiency of handling. I looked at several different makes and it was seeing a Striebig being used that proved to me it was tough enough for the job.”

In particular he singled out for praise the saw’s digital readout facility, which provides total accuracy.

“It has certainly led to a marked increase in efficiency; halving the time it takes to size a door,” he said. “It’s also labour saving. We needed two men to put a door in place on the table saw and then hold it steady whilst it was being sized. It’s a one–man job with the Striebig.”

He said another benefit is that there is no need to move the door around once it has been placed on the saw, so there’s far less much chance of damage occurring.

The Evolution is one of the most advanced manual panel saws available, representing the cutting edge in vertical panel saw technology.

Features included as standard include the digital measuring system, accurate to 0.1 mm, and an adjustable precision display that can be set to an accuracy of 1.0, 0.5 or 0.1 mm, according to the thickness of the panels being sized.

Numerous automatic procedures carried out by the press of a button include locking and releasing the saw beam, setting the horizontal cutting height, plunging and swivelling the motor, locking the support rollers during sawing and fine saw blade adjustment.

Designed to be wall-mounted or freestanding, it has a fully automatic roller locking function, an auxiliary stop section with its own tape measure, three additional auxiliary stops for repeat cuts and a small work piece support.

Fitted as standard is the TRK dust and chips extraction system that ensures dust levels are kept well below permitted European limits, and automatic moving backing support.

Amongst the wide number of options available to increase productivity still further is four-side trimming, which enables the bottom trim cut to be carried out automatically without having to lift or turn the panel.

The Evolution was supplied and installed by Striebig’s exclusive UK distributor, Leicester-based T.M. Machinery Sales.

For further information contact Matt Pearce, Sales Director on 0116 271 7155 or email sales@tmservices.co.uk

Issued by Stephen Barry Publicity. Tel: 020 8341 6660. Email: stephenbarry@clara.co.uk