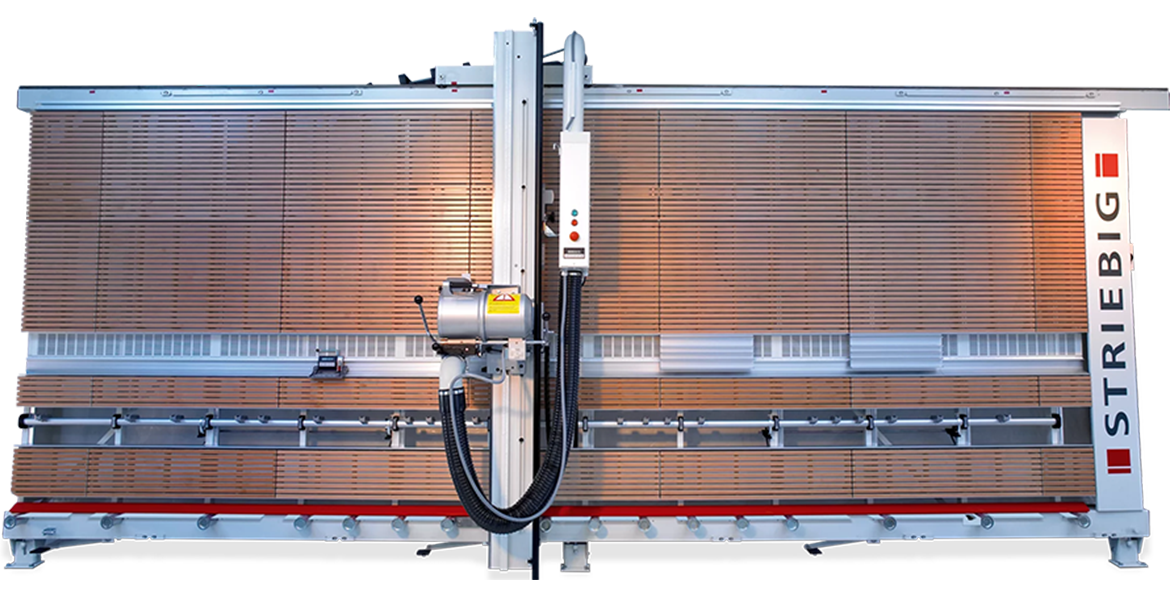

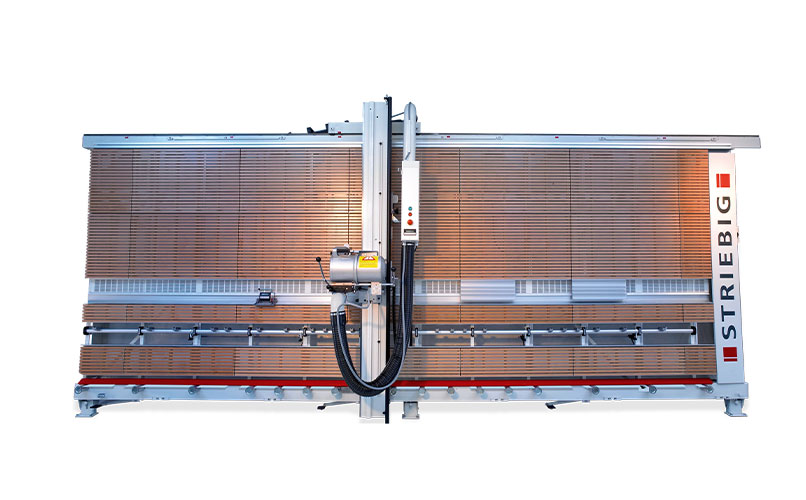

Swiss manufactured Vertical Panel Saws are the world's most technologically advanced, economically efficient, and precise machines.

find out more

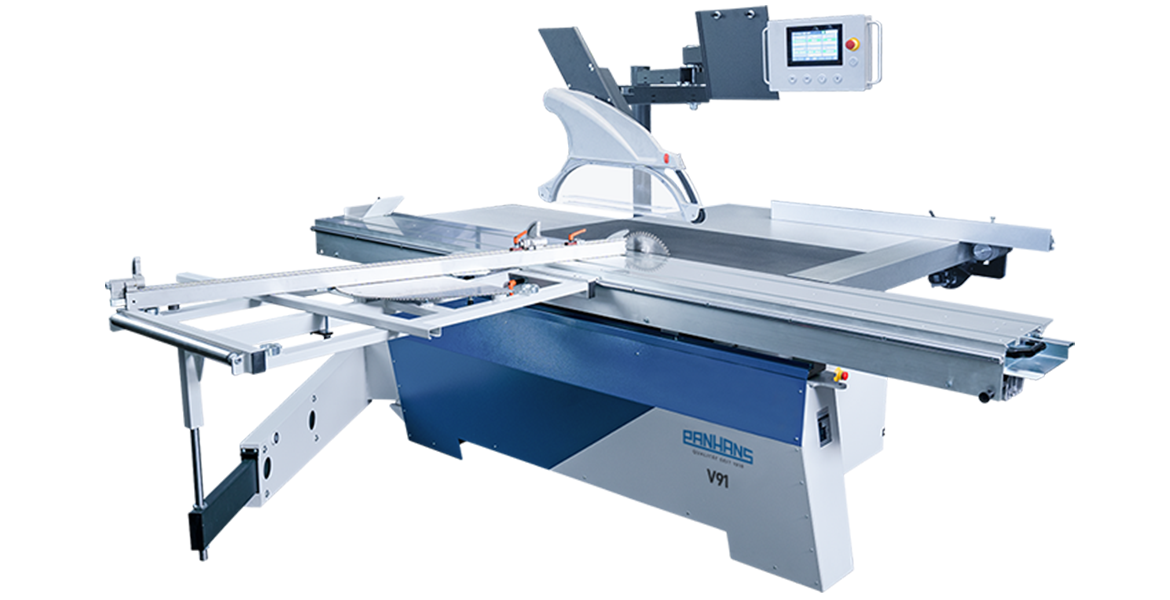

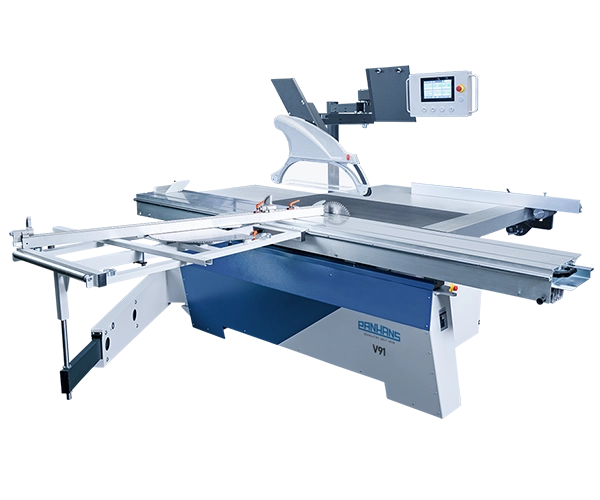

An essential workshop machine, for cutting wood, plastics, composites or MDF.

find out more

Find solutions for all aspects of extraction technology from compact units to central extraction systems, for virtually every conceivable application.

find out more

A range of spindle moulder machines from leading manufacturers for cutting profiles into wood, plastics or other materials.

find out more

Since 1983, TM Machinery has been a trusted supplier of woodworking machinery equipment in the UK.

As leaders in our field, we have built a solid reputation for providing top-quality machines and excellent customer service to our clients.

Whether its saws, dust extraction systems, or any other specialist woodworking machinery, TM Machinery has the expertise and products to meet your needs.

With a team of experienced engineers, we also provide installation, servicing, and maintenance to ensure your equipment operates optimally for years to come.

We supply high quality new and used industrial woodworking machinery including vertical panel saws, sliding table saws and dust extraction systems to companies across the UK.

As an independent supplier of woodworking machinery, we take pride in the quality of our products, and we believe that our selection of machinery from the finest manufacturers across Europe sets us apart from the competition.

Our manufacturers are specialists in their respective fields, which means that the machinery we offer you is designed and built with the latest application engineering and technology.

Our team of experienced engineers and apprentices work all over the UK and can service and maintain a wide range of industrial woodworking machinery.

We have specialist mobile engineers available nationwide and a dedicated and well-stocked spares department.

Our training and experience in the industry sets us apart from our competition – with diverse backgrounds in woodworking machinery and mechanical and electrical engineering, the team understands the importance of getting the job done quickly and efficiently.

Leading woodworking machinery and dust extraction supplier, TM Machinery, will be exhibiting at the UK’s only woodworking machinery and components show, the Materials & Finishes Show (formerly W Exhibition) this May at the Birmingham NEC.

Representing not one but two industry-leading brands at the four-day event, the Leicester-based machinery distributor will be showcasing its exclusive range of cutting-edge filtration systems and dust extractor units from AL-KO – including the versatile Power Unit range – and a selection of Striebig vertical panel saws – from the market leading Compact model to the best-selling Control.

For more information on our woodworking machinery sales and services contact us today.

T.M. Machinery supply high quality new and used industrial woodworking machinery including vertical panel saws, sliding table saws and dust extraction.

In addition to the products we supply, we also have a large team of engineers providing repair and maintenance services for a wide range of woodworking machinery.