Read what respected trade publication Furniture Journal has to say about the Striebig Control Vertical Panel Saw.

Swiss made, the Striebig Control Saw is proving popular with British furniture manufacturers – and not just for its precision and build quality. Chris Price from cabinet-makers James Burleigh purchased a Striebig Control 5168 to cope with the cutting of large dimension 3mm thick laminate panels.

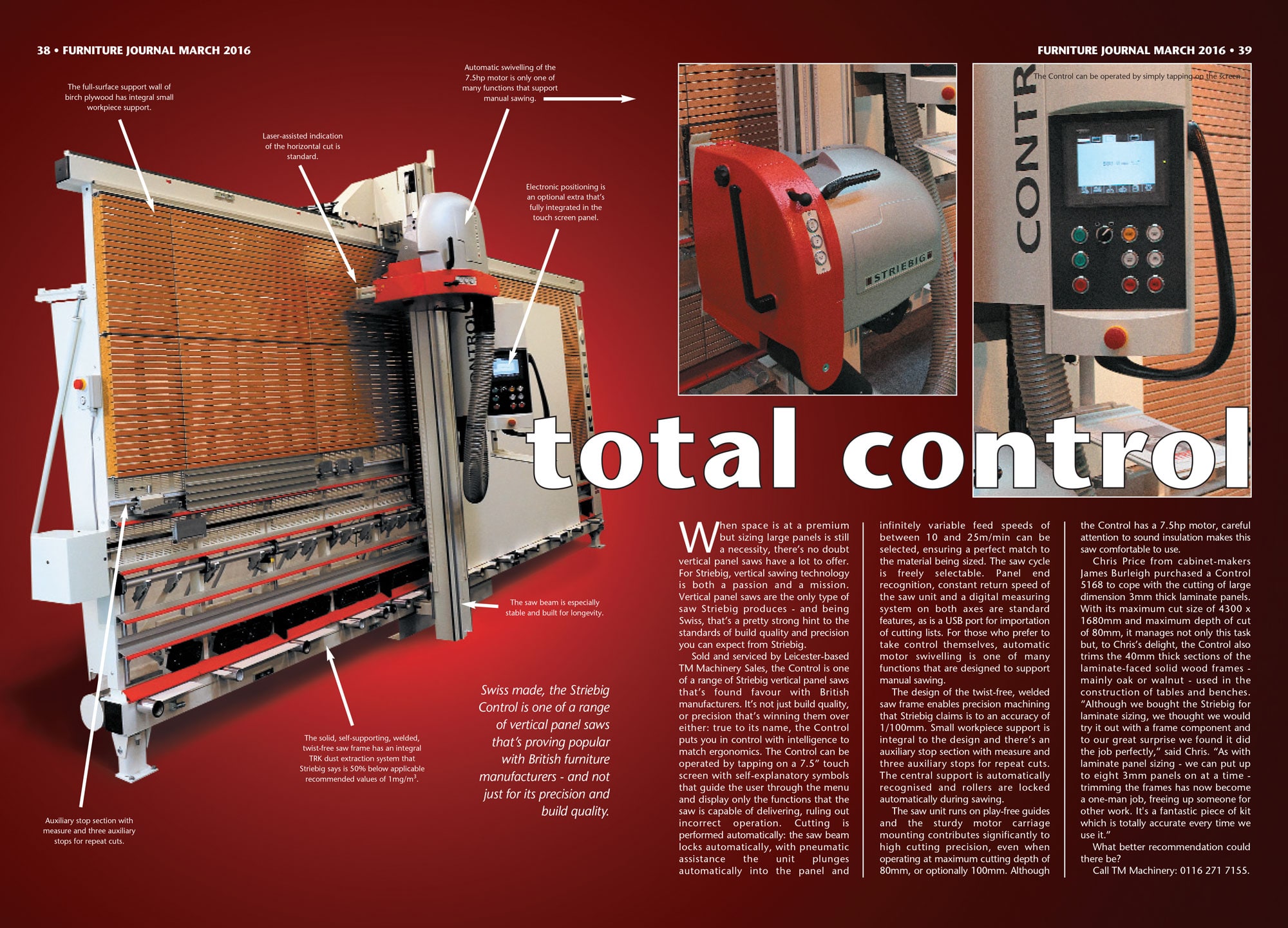

Total accuracy with the Striebig Control

With its maximum cut size of 4300 x 1680mm and maximum depth of cut of 80mm, it manages not only this task but, to Chris’s delight, the Control also trims the 40mm thick sections of the laminate-faced solid wood frames – mainly oak or walnut – used in the construction of tables and benches.

Says Chris, ”It’s a fantastic piece of kit which is totally accurate every time we use it.”

The new and improved Striebig Control vertical wall saw is a comprehensive vertical cutting centre designed to meet the demanding needs of today’s panel processors. It sets itself apart from other vertical panel saws with its high degree of automation and user-friendly operations that deliver secure and risk-free operation. With the Control, manual work is a thing of the past, guaranteeing that sizing is performed easily and quickly.

For further information contact Matt Pearce, Sales Director on 0116 271 7155 or email sales@tmservices.co.uk

Issued by Stephen Barry Publicity. Tel: 020 8341 6660. Email: stephenbarry@clara.co.uk