In today’s competitive woodworking landscape, skill alone isn’t enough to keep up with rising demand. As labour costs and manufacturing challenges increase, the smart move for forward-thinking businesses is to invest in high-tech machinery—and here’s why.

High-tech machinery with automation is more than just tools—they’re solutions. Take cutting tasks, for example. Without fast, accurate cutting of panels, the rest of your production process is held up.

By automating routine processes, you not only boost output but also increase the precision and consistency of your work, helping you meet customer demands faster while reducing errors and material waste. This means more profitability with fewer resources. Put simply, allowing your team to accomplish more with less.

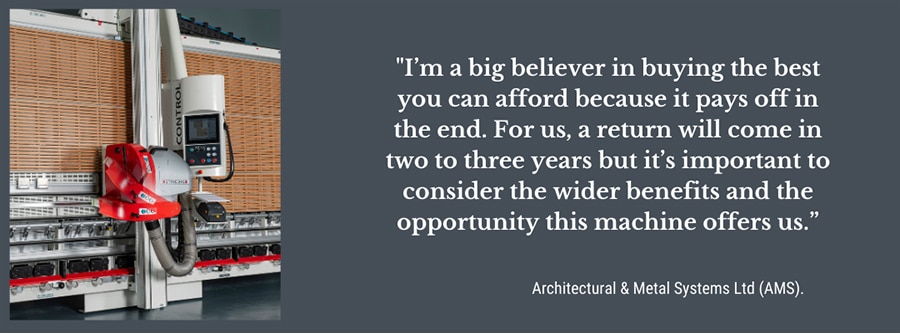

That’s where the Striebig Control and Striebig 4D Vertical Panel Saws come in, equipping woodworking operations with advanced precision, along with cutting-edge automation with the flexibility to adapt to your business needs. These systems not only streamline production but also improve overall performance in ways you may not expect.

Here’s how:

Precision Cutting

With ±0.1mm tolerance: Both models ensure highly accurate cuts, ideal for cabinetry and custom woodworking needs.

Speed & Efficiency

Striebig Control: Achieves cutting speeds of up to 25 m/min with automatic saw beam positioning, significantly improving production efficiency. This precision-driven automation reduces human error and ensures consistent cuts, enhancing throughput and streamlining operations for businesses looking to maximise productivity.

The Striebig 4D: Boosts productivity with fully automated saw beam positioning, and its optional features like PAV panel lowering and PPS panel feeder enhance automation across both vertical and horizontal cutting. This streamlined approach significantly increases production efficiency, optimising throughput and reducing bottlenecks in the workflow.

Automated Cutting Programmes

Both models support fully automated cutting sequences. Once a program is set, the machine handles the rest. You’ll eliminate errors, speed up processing and free up employees for more complex tasks.

Material Optimisation

Smart software optimises cutting plans, reduces material waste and increase efficiency. You’ll reduce costs and increase sustainability.

User-Friendly Touchscreen Interface

The easy-to-use touchscreen allows operators to quickly program and adjust cuts with minimal training. This reduces setup time, increasing efficiency on the workshop floor.

Labour Efficiency and Reduced Vulnerability

Striebig automated panel saws are designed to reduce reliance on multiple operators. Capable of being operated by a single person, these saws help businesses cut labor costs while maintaining high production standards. This also minimizes workforce vulnerability, as one operator can efficiently manage the entire cutting process, eliminating the need for constant supervision or extra staff for routine tasks.

Versatile Material Handling

These Swiss saws are engineered to manage wood, laminates, MDF, non-ferrous metals, acrylic and plastics, allowing for flexibility and increased project capabilities without outsourcing.

Advanced Dust Extraction

Meeting health and safety standards, Striebig’s innovative design features an integral dust extraction system, maintaining a cleaner, safer workspace.

Predictive Maintenance – An Unexpected Benefit of Automation

One significant, yet often overlooked, benefit of automation is predictive maintenance. By integrating sensors and diagnostics into the Striebig machines, they can monitor performance in real time and alert operators to potential issues before they cause downtime. This not only reduces the risk of costly repairs but also helps optimise the machine’s overall efficiency.

Predictive maintenance works in tandem with the automated systems, keeping your saws running smoothly without relying entirely on operator intuition or manual checks. In fact, this feature is an excellent example of how automation doesn’t just improve speed and precision but also helps with long-term reliability—a benefit that many businesses may not immediately consider when investing in automation.

Automation with Striebig: More Than Just Precision

Striebig vertical panel saws elevate your business with automation that tackles repetitive tasks, such as panel handling, precision cutting and material optimisation. But beyond just speeding up the process, automation enhances flexibility. You can tweak and fine-tune the saws with a variety of optional extras, ensuring that your equipment perfectly matches your production requirements. Whether you choose the Striebig 4D or Striebig Control, you can customise your machine to meet your unique needs, from increased throughput to optimised material handling.

Striebig Flexibility: Tailored Automation Across the Range

Automation doesn’t mean a one-size-fits-all approach. Striebig machines are designed to be customisable with optional features that suit a wide range of production needs. From advanced cutting software to integrated dust extraction systems, you can easily adapt your machine to match the changing demands of your operation.

- The Striebig 4D offers fully automated panel handling and cutting optimisation, allowing for faster production times and reduced labor costs.

- The Striebig Control provides a more hands-on approach with automated support, helping skilled operators maintain high standards of quality while increasing efficiency. This adaptability means that whether you’re handling high-volume cuts or custom, smaller orders, Striebig can adjust to your needs—without compromising on quality or precision.

Conclusion

The Smart Choice for the Future of Your Woodworking Business Investing in Striebig vertical panel saws is not just investing in a new machine—it’s about futureproofing your business with automation that adds value in multiple areas.

From improving cutting precision to optimising material usage and reducing your vulnerability to employment issues, these machines are designed to support your business’s growth.

And with the highest build quality and predictive maintenance, Striebig offers peace of mind, ensuring your machines remain in top condition without extra effort.

Don’t just invest in machinery—invest in the future of your business. Striebig vertical panel saws help you achieve faster production, improved quality, customisation, flexibility and greater cost efficiency.

Contact TM Machinery Today

Ready to transform your woodworking operation? Talk to TM and discover how the automation within Striebig’s range of vertical panel saws can help streamline production and increase your business’s potential.