Refurbished Striebig Saw Helps Emerys Boost On-Site Cutting Service

In recent years, Emerys Timber and Building Merchants has seen its on-site cutting service grow in popularity. But, with an aging vertical panel saw that was no longer the steadfast workhorse it once was and order numbers increasing, it turned to TM Machinery – the exclusive distributor of Striebig vertical panel saws – to find not only a reliable cutting solution but also a dependable service partner.

A Reliable Replacement for a Long-Serving Machine

“After 20 years, our old vertical panel saw had passed its best,” begins Lee Rowland, Machinery Operator at Emerys Timber and Builders Merchants. “It was easy to maintain and with a little TLC, it ran and ran but we knew we were living on borrowed time.”

Why a Refurbished Striebig Caught Their Eye

The Stoke-based merchants originally looked at purchasing a brand new Striebig vertical panel saw, but it was a used Compact model being refurbished in TM Machinery’s Leicester showroom that caught their attention.

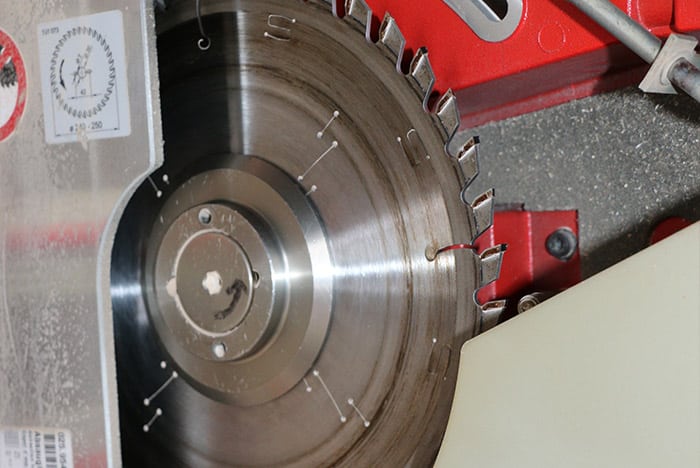

“After being impressed by a demonstration on a new Striebig, we spent some time watching one of the engineers strip down a used machine that had just come in,” says Lee. “He was going through each part of the saw methodically – cleaning, checking and replacing parts as he went. This wasn’t just a quick wipe down – it was a rebuild. It was clear he knew this saw inside out.”

Performance, Price and Practicality

With a competitive price tag, a 6–8 week lead time and a warranty included, the decision was made to purchase the refurbished model.

“It did everything we needed it to do. It could cut 8×4 MDF up to 25mm thick quickly and accurately, cope with upwards of 180 boards at a time and required minimal training to use competently.”

Space-Saving Footprint and Easy Installation

Its compact footprint also sealed the deal.

“Most of the other vertical panel saws we looked at protruded 1700–1800mm off the wall. The Striebig was only 900mm,” Lee explains. “It meant we could make the most of the space and still keep access to an external door clear. The decision was a no-brainer.”

Following installation and training, the saw was immediately put to work. “It does a day’s work without missing a beat,” says Lee. “It’s as good doing a single cut as it is a hundred.”

Better Handling, Less Strain and Simple Operation

Lee continues, “It’s made our lives so much easier. It goes without saying that the Striebig is quicker, easier to handle and lighter to use. There’s no strain on your arms or back thanks to the ball-bearing support rollers and manoeuvrable motor head. There’s also no fancy screens or unnecessary technology. You set the measurements and get cutting. We can maintain the saw ourselves without relying on engineers for minor jobs.”

Small Features Making a Big Difference

Lee highlights several design touches that improve accuracy and workflow.

“Take the length stop – a simple but super effective tool to keep boards in place when cutting. Then there’s the strip cutting gauge for repeat cuts without constant adjustments.”

Another major improvement came from the cutting position. “Before, we always cut from the bottom and the weight of the board caused inaccurate cuts and extra strain on the blade. The Striebig cuts from the top, eliminating this problem completely.”

Dependable Support from TM Machinery

TM’s aftercare sealed the partnership. “We were looking for a company that sold machines and serviced them. TM started as a servicing company, so they know Striebig machines inside out. They offer a great package.”

A Future-Proof Investment

Lee concludes, “I can’t fault the machine in any way. When it arrived, it looked like new and it continues to perform accurate cuts daily. With a service plan in place through TM, I’m confident this saw will last us a long time.”

Contact TM Machinery for More Information

Ready to transform your woodworking operation? Talk to TM and discover how the automation within Striebig’s range of vertical panel saws can help streamline production and increase your business’s potential.