Smart, Scalable Factory Design

Morro Partnerships set out to build a factory that was smart, scalable and efficient — not just large. Their 8,000 sq ft Innovation Hub was designed around real production needs, keeping workflows tight, material movement simple and overheads low. Every decision was made with 20+ years of manufacturing experience in mind, ensuring the space could support growth without unnecessary waste.

Cleaner Air, Lower Energy Costs

A key part of this strategy was investing in reliable, long-term machinery. Morro chose an AL-KO air-handling and dust-extraction system to keep the factory clean, protect staff, and minimise energy loss. This was especially important in a low-ceiling environment, where poor airflow could quickly impact safety or working conditions. With the system in place, the team benefits from consistent air quality and reduced running costs.

Faster, More Accurate Production

For cutting and sizing, the company installed a Striebig vertical panel saw. The saw processes 30–50 panels a day with repeatable accuracy, supported by a mechanical sliding stop and integrated label printing. Together, these features help reduce errors, speed up production, and support a more streamlined, paper-free workflow across the factory floor.

Built for Sustainable Growth

According to Morro, the real win comes from the combination of smart layout, the right machinery, and dependable service from TM Machinery. Rather than chasing flashy automation, the business focused on safe working conditions, low downtime, and systems they can trust every day — all crucial foundations for sustainable expansion.

Find out More

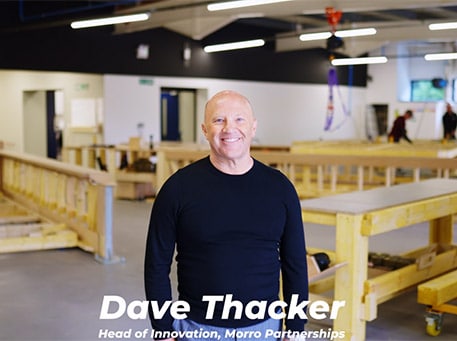

Read the full article here: Morro Partnerships Innovation Hub or watch a recent interview with Dave Thacker from Morro on why they chose to work with TM Machinery.

Contact TM Machinery for More Information

Ready to transform your woodworking operation? Talk to TM and discover how the automation within Striebig’s range of vertical panel saws can help streamline production and increase your business’s potential.