When deciding on the best saw for your woodworking shop, you might find yourself asking: should I invest in a vertical panel saw or a sliding table saw?

Both saws have their advantages, but understanding the specific benefits and limitations of each saw can help you make an informed decision that enhances efficiency, safety, and precision in your operations.

Space Efficiency: Comparing Vertical Panel Saws to Table Saws

One of the main considerations for any workshop is space. Vertical panel saws, like those offered by Striebig, are designed to operate in a minimal footprint, needing only 7 square meters of space, even when cutting large sheets measuring 2800 x 2070 mm. In contrast, a sliding table saw can require up to three times as much space, making the vertical option far more efficient for smaller workshops or those looking to maximize space.

The compact design of the vertical panel saw not only saves space but improves the layout of your workshop. You can allocate more room for other essential tools and materials, improving overall workflow and productivity.

Which Saw is Best for Cutting Larger Sheets to Size?

In contrast, a sliding table saw requires more manual intervention. Sheet material must be manually positioned and fed through the blade, which increases the chances of misalignment and errors, especially when dealing with large sheets.

Easy Manual Handling and Accurate Cutting of Sheet Material

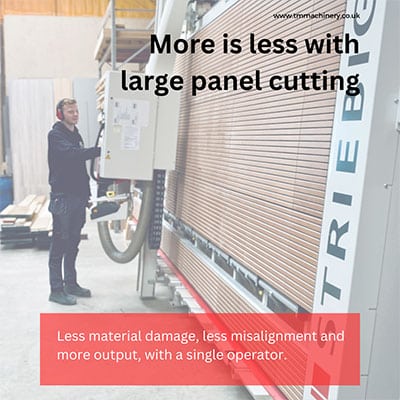

Efficient woodworking and joinery businesses need saws that are easy to use and assure precision cutting, so material handling is a critical consideration when choosing between saw types. The Striebig vertical panel saw features a moving saw head which significantly reduces the manual handling of materials. The operator simply positions the sheet onto the datum edge, speeding up the process and minimising misalignment risks.

In contrast, sliding table saws require more manual labour and effort. The saw blade remains stationary while operators must carefully position and feed the material through the blade for every cut. This setup also demands more physical space and operator skill to achieve accurate cuts. A second operator is often required, especially for jumbo sheets, further complicating the process.

Cut Quality: How Automation Improves Your Panel Cutting

Both saw types require a high-quality, vibration-free blade and appropriate blade speeds for accurate cuts. However, with sliding table saws, feed speed depends on the operator’s skill, often leading to inconsistent results, especially when processing challenging materials or large sheets.

By contrast, the Striebig vertical panel saw range offers automated cut cycles with precisely controlled feed speeds, ensuring consistent, high-quality cuts every time. Whether you’re cutting thick plastics or large panels over six meters long, the automated features of a vertical panel saw reduce operator error and deliver consistent and precise cuts.

The Disadvantages of a Table Saw

- Space Requirements: sliding table saws require significantly more space than a vertical panel saw, limiting their suitability for smaller workshops. Additionally, you need extra floor space to manoeuvre large sheets.

- Manual Handling: Feeding materials through a stationary blade is labour-intensive and often requires more operators for large sheets, increasing the risk of errors.

- Operator Dependency: Cut accuracy largely depends on the operator’s skill, and variability in feed speed and material positioning can lead to inconsistent cuts and material wastage.

- Safety Concerns: The exposed blade on a sliding table saw poses a higher risk of injury when compared to the enclosed blade of a vertical panel saw. Additionally, the physical effort required to operate a sliding table saw can lead to tiredness and higher risk of potential accidents.

Choosing a Vertical Panel Saw: Important things to Considerations

Selecting the right vertical panel saw involves several factors:

- Space Availability: Ensure enough vertical space for operation and material handling. You’ll need to factor in room to load, operate, and unload the machine.

- Material Types: Striebig saws handle a wide range of materials, including wood, plastics, and composites, making them versatile for various applications. If you outsource cut-to-size materials, choose a vertical panel saw that can bring cutting in-house.

- Automation Features: With the Streibig range of vertical panel saws, you can select and optimise your panel saw to your exact manufacturing needs. Advanced automation like automatic positioning and laser-guided indicators enhance precision, reduce operator error, and improve overall productivity.

- Budget: While both vertical panel saws and table saws are similarly priced at the premium level, the vertical panel saw offers better long-term savings. By improving efficiency, reducing material wastage, and lowering staffing needs, you’ll see a stronger return on investment (ROI) over time.

Automation and Technology: Leading the Way with the Vertical Panel Saw

This level of automation not only improves accuracy but also reduces the skill level required to operate the saw, making it valuable for workshops of all sizes.

While sliding table saws may offer limited automation, such as the positioning of stops, vertical panel saws like those in the Striebig range take automation to the next level with a wealth of automated features that include:

- Automatic positioning of digital measuring stops: Ensures precision and repeatability in cuts.

- Fully automated cut cycles: Minimises operator involvement and reduces the potential for errors.

- Laser-guided indicators: Assist in the accurate positioning of materials before cutting.

- Pneumatically-braked support rollers: Enhance material stability during cutting.

- Automatic trimming functions: Improve efficiency and reduce waste.

Intelligent features can be teamed with software that controls saw function, with options to optimise parts lists with CAD and ERP software programmes, and automatically create cutting plans. With automated Striebig vertical panel saws, manufacturers can streamline processes and benefit from industry 4.0 manufacturing processes.

Safety: Protecting Your Employees from Woodworking Accidents

According to statistics from the HSE, the woodworking industry has one of the highest accident rates in manufacturing, with many incidents related to contact with moving machinery.

Vertical panel saws are designed with operator protection in mind. Unlike sliding table saws, where the blade is exposed during operation, a vertical panel saw’s blade is fully enclosed within its housing. This important feature minimises the risk of accidental contact with the blade, significantly reducing the likelihood of injury.

Striebig go even further by incorporating advanced safety features, such as a mechanism that prevents the saw from being turned on if the housing is open or unlocked. This provides additional protection for your employees.

Manual Handling in Woodworking: Reducing the risk

Reducing manual handling is crucial for safety in woodworking and joinery shops, where back injuries from lifting heavy, awkward materials are common. Every year, 300,000 UK workers suffer from back pain due to manual handling accidents. A vertical panel saw, with its ergonomic design that allows the saw head to move instead of the material, significantly reduces physical strain. This not only improves workplace safety but also minimizes the risk of injury-related absences, keeping your operations smooth and your team healthy.

Vertical Panel Saw V Sliding Table Saw: The Best Investment?

When considering productivity and reduced manual hours, many Striebig users report an impressive ROI over a shorter period than imagined. While a table saw may seem cheaper at first glance, it can quickly become more costly than investing in the right machine

The efficiency gained from a vertical panel saw means your team can produce more in less time, freeing up skilled workers to focus on higher-value tasks. This improved workflow speeds up output and allows you to utilise your team’s capabilities, leading to greater overall performance and job satisfaction.

Conclusion: Choosing the Right Saw

Choosing between a vertical panel saw and a sliding table saw depends on your specific manufacturing needs. However, for those looking for space efficiency, precision, safety, and long-term cost savings, a vertical panel saw is the strongest contender.

Vertical panel saws, particularly the Striebig, with advanced capabilities, precision, ergonomic design, automation features, and optional extras make the vertical panel saw, a wise investment for any woodworking business and joinery workshop.

A Word from TM Machinery, specialist woodworking machinery supplier

Matt Pearce, Managing Director of TM Machinery, emphasises the advantages of choosing a Striebig vertical panel saw: “The space-saving element of a vertical panel saw should never be overlooked, but there are so many more benefits a Striebig can offer. Comparable in price to a sliding table saw but offering a different approach to cutting sheets to size, a Striebig saw removes many of the issues associated with cutting large panels, guaranteeing accuracy within 0.1mm on every cut.”

Matt continues, “The finish of the cut means the board can be put straight through an edgebander without further machining or hand-finishing, offering the user a wealth of possibilities when using panels, composites, plastics, and metals. To see the results for yourself, consider booking a demonstration at TM Machinery’s Leicester showroom, and explore the full capabilities of a Striebig vertical panel saw.

Contact TM Machinery Today

For more information on the wide range of Striebig Vertical Panel Saws and Dust Extraction units available exclusively from TM Machinery please contact us today.