Investing in the right dust extraction for your workshop isn’t always a straightforward process. Here, we ask Matt Pearce, Managing Director of TM Machinery and the exclusive distributor of AL-KO dust extraction units in the UK, to breakdown the key factors to consider before making your purchase.

“When it comes to choosing the right dust extraction model for your business, it’s important we ask our customers the right questions,” begins Matt. “What material are you processing? How many machines do you need to run at once? Will the machines run all day? And, how big is your workshop? These questions will ultimately determine the right dust extraction solution for you.

“From a customer’s stand point, it is important to consider plans for the future. Are you looking to add more or different machines to your factory floor, increase production or change your offering? Thinking long-term could save you time and money but we appreciate this is often easier said than done.”

AL-KO Power Unit Range

That’s where mobile units like the AL-KO Power Unit range come into their own. With a static system, future expansion isn’t always straightforward. Matt explains, “You have to consider ducting extensions, space for a bigger unit and design and installation costs. With a movable unit, you have the flexibility to add and use multiple power units within a workshop as and when required.” Matt adds, “It’s like a plug-and-play concept. It’s quick and easy to install and it only requires a small footprint.”

That’s where mobile units like the AL-KO Power Unit range come into their own. With a static system, future expansion isn’t always straightforward. Matt explains, “You have to consider ducting extensions, space for a bigger unit and design and installation costs. With a movable unit, you have the flexibility to add and use multiple power units within a workshop as and when required.” Matt adds, “It’s like a plug-and-play concept. It’s quick and easy to install and it only requires a small footprint.”

In addition to this, you must consider if your investment is future proofed. Each AL-KO Power Unit model has been designed and tested in accordance with the European Norm EN 16770 – a regulation that was updated in December 2018 to highlight new risks associated with modern manufacturing – as well as all national standards and CE requirements. “This means AL-KO’s range has been designed to return air that far cleaner than the requested value UK manufacturers need to meet by 2024 – making the AL-KO brand a sound, future-proofed investment for any manufacturer,” says Matt.

Then there are the day-to-day running costs, ongoing cleaning and maintenance to consider. “With energy bills rocketing, it has never been more important to consider a greener, more cost-effective solution” warns Matt. “Customers often focus on motor sizes when investing in a new extraction system. However, with improved air flow and fan housing design this is becoming less relevant and doesn’t reflect the overall performance of a dust extraction unit. AL-KO’s optimised fan housing coupled with GS and H2 marked energy-efficient motors save energy while still guaranteeing 100% air recirculation without loss of temperature.”

AL-KO’s Opti Jet

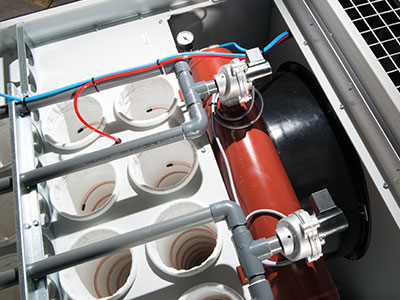

Each Power Unit incorporates AL-KO’s Opti Jet®, a unique, high-performance filter cleaning system that offers optimum filter cleaning whilst using the least amount of compressed air possible. Its design – which centres around a large air surge tank – has also been created to reduce energy consumption without comprising on performance. “The Power Unit range also offers integrated frequency converters,” says Matt. “This means the fan only produces the required flow, saving energy and increasing the service life and overall health of the filter.”

Each Power Unit incorporates AL-KO’s Opti Jet®, a unique, high-performance filter cleaning system that offers optimum filter cleaning whilst using the least amount of compressed air possible. Its design – which centres around a large air surge tank – has also been created to reduce energy consumption without comprising on performance. “The Power Unit range also offers integrated frequency converters,” says Matt. “This means the fan only produces the required flow, saving energy and increasing the service life and overall health of the filter.”

AL-KO Safety Features

Safety features should also be taken into account, as well as any unexpected extra-cost safety options. “One of the main risks when extracting wood dust is the threat of explosions and fire. To tackle this, AL-KO’s units feature an outer shell that is pressure shock resistant meaning it can be installed in the workshop without external explosion relief. Power Unit models from 250 upwards are also equipped with a thermal sensor and integrated fire extinguishing system. Plus, all models now come with dust compartment sealing plates as standard and optional filling level sensors to reduce dust exposure when emptying and to prevent blockages inside the filter housing.”

AL-KO Product Servicing

Finally, Matt firmly believes that aftercare should not be overlooked. “Does your extraction brand have specialists in the UK that can come and service your unit quickly? Do they carry spare parts? And do they offer a warranty? For TM Machinery, the answer is simply, yes. As the exclusive UK distributor of AL-KO dust extraction units, we know our product range inside out and our engineers have been trained directly by AL-KO. We offer a reliable, trusted service which is a must when working with any business. As a result, we can offer our customers the very best German-engineered dust extraction solutions that will stand the test of time and the ongoing changes to workplace law in the UK.”

For more information please call +44 (0)116 271 7155 or email sales@tmservices.co.uk.

For the latest news, follow TM Machinery on Twitter: https://twitter.com/tm_machinery.