Timber-frame specialist Frame Wise Ltd has installed a Striebig vertical panel saw and an H&M Anglemaster CNC upstroke cross-cut saw as part of an upgrade package of its production machinery.

Bought at a combined cost of £80,000, they have allowed the company to simplify its manufacturing operations. Set up in 1997, Frame Wise designs, manufactures and erects timber-framed projects throughout the UK. After starting out by supplying the domestic self-build market it has expanded its operations to cover the commercial and public sector. It is strongly customer focussed and as a member of the UK Timber Frame Association (UKTFA) has achieved the Q Mark for quality.

It has carried out contracts ranging from the restoration and extension of a 16th cottage through to the construction of a 60 bedroom nursing home. It’s now well established in the local authority market, with a preferred supplier agreement in place for the supply of school buildings including a recently completed £3m new school in Gloucester.

The timber-frames are made at four adjacent units in Presteigne, Powys, with the company due to move into a new, purpose-built 25,000 sq. ft. building starting later this year. Managing director Simon Orrells, who sits on the board of the UKTFA, has a firm policy of ensuring that only the latest machinery is used to produce the highest quality product.

He said: “As our sales are growing rapidly I wanted a panel saw that could cope with all the new business, taking into consideration our space limitations. I also needed to streamline the cutting of the panels’ timber studs and rails. I believe in buying the very best equipment I can afford and both the Striebig and the Anglemaster offer quality, speed, are easy to use and are highly reliable.

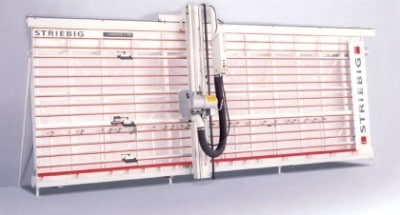

Striebig Standard

“Its space-saving Striebig Standard II TRK 6206, which replaced a beam saw, handles OSB sheets up to a maximum size of 5300 x 2060 x 80mm thick. They are used as external building panels to give structural integrity, meet fire regulations and to seal wall cavities.

The Standard II was supplied by the Striebig’s exclusive UK agent, T.M. Machinery Sales, of Leicester.

It comes in a choice of nine frame sizes, two frame types, two motor sizes and three extraction systems, amongst many other options. High safety standards and ergonomically positioned controls are typical features of Striebig’s highly advanced design technology, making the Standard II exceptionally easy to operate and safe to use, minimising operator fatigue and avoiding costly errors.

TRK Extraction System

Standard features include the TRK extraction system – to keep users ahead of the latest European legislation – and automatic moving backing support.

It has transformed what was a two-man job with the beam saw into one-man operation The operator cuts all the sheets needed for the next order and is then freed up to cut the floor joists on a Maggi Junior radial arm cross-cut saw.

Said production manager David Lording: “The Striebig is strong and robust and has no problem cutting through the tough 2.4 x 1.2m (8 ft x 4 ft) OSB sheets, which range in thickness from 9 to 18 mm. We can put the 9 mm thick sheets on the saw six at a time.

“Its accuracy is much better than the beam saw and gives us edges so smooth that when panels are joined together you can’t see the joins. It’s also easy and safe to use because of its advanced design, with little physical effort required by the operator.”

After being cut to the required size the OSB sheets are sent to the fabrication shop where the timber studs and cross rails, prepared on the new H&M Anglemaster CNC cross-cut saw, are fitted.

The Anglemaster was supplied by JJ Smith Woodworking Machinery Ltd of Liverpool. It replaced a series of smaller hand-operated saws and, like the Striebig, has made the cutting operation far more efficient with the added benefit of safer working.

Optimaster Software

The tight integration offered by the Anglemaster’s Optimaster software was what first attracted Mr Orrells. The Optimaster software enables timber to be pre-optimised prior to cutting, allowing accurate estimation of timber yields and usage. The saw is also equipped with an in-line ink jet printer for marking the panel identifiers and stud positions on the top and bottom rails. A rotating saw bed enables angles for gable panels as well as straight cuts to be carried out in the same cutting program.

Said Martin Smith, JJ Smith’s Managing Director: “By specifying a machine specifically for the timber frame industry we were able to offer a dedicated machine with all the correct features for the manufacture of timber frame components.”

The productivity gains provided by the introduction of the two new saws will ensure that Frame Wise remains a market leader in the rapidly growing timber-frame sector.

For further information contact Matt Pearce, Sales Director on 0116 271 7155 or email sales@tmservices.co.uk

Issued by Stephen Barry Publicity. Tel: 020 8341 6660. Email: stephenbarry@clara.co.uk