TM Machinery’s Guide To Vertical Panel Saws

In modern woodworking and panel processing, precision, safety, and space efficiency aren’t just nice-to-haves; they’re essential. For businesses looking to optimise their workflow, reduce waste, and improve output quality, the choice of machinery is a critical decision.

That’s where the vertical panel saw comes into its own, offering a powerful solution that addresses the key challenges of today’s workshops.

One of the standout advantages of vertical panel saws is their space-saving design, requiring minimal floor space, often as little as 5 m², making them ideal for workshops with limited space compared to larger, traditional saws.

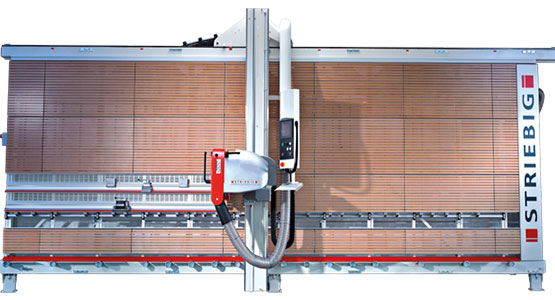

As the exclusive UK distributor of Striebig Vertical Panel Saws, TM Machinery is uniquely positioned to help businesses unlock new levels of productivity, achieve unparalleled cut quality, and optimise their workshop layout.

This comprehensive guide will explain what a vertical panel saw is, explore its numerous benefits, detail how TM Machinery supports customers from sale to service, and demonstrate why the Swiss-engineered Striebig range is the top choice for professionals.

What Is a Vertical Panel Saw?

A vertical panel saw is an industrial cutting machine designed for panel cutting, making it ideal for sizing large sheet materials with precision. Unlike traditional table saws, where the material is pushed across a flat table, a vertical panel saw holds the panel upright (vertically) against a sturdy frame, providing stable working areas for various panel sizes.

The saw head, mounted on a moving beam, travels along a track to make precise horizontal and vertical cuts. Vertical cutting is a key feature, allowing for accurate and space-saving processing of tall panels.

The cutting range of the machine determines the maximum panel length it can accommodate, often up to several meters, making it suitable for large-scale projects. The blade diameter and saw blade diameter are important technical specifications, with many models supporting blades up to 250 mm, and a maximum cutting depth of 60 mm. For enhanced precision, an optional scoring unit can be included.

The central support ensures stability during cutting operations, especially with heavy or oversized panels. Different types and models of vertical panel saws are available to suit various needs, and the ergonomic design makes operation easy and efficient.

Because the frame is designed to sit flush against a wall, these machines are often called wall saws. This design is a game-changer for workshops where floor space is at a premium.

Furthermore, the versatility of a vertical panel saw extends beyond just wood; they are engineered to cut a wide variety of materials, including plastics, laminates, and composite panels like ACM, with exceptional accuracy.

How Does a Vertical Panel Saw Work?

The operation of a vertical panel saw is designed for efficiency, accuracy, operator safety, and easy use thanks to user-friendly controls and ergonomic design.

The process generally follows these steps:

- Loading the Panel: The large sheet material is loaded onto the machine and rests vertically on a series of support rollers at the base of the frame. An adjustable central support ensures stability during loading and cutting, minimising manual lifting and making handling heavy or awkward panels significantly easier.

- Positioning for the Cut: The operator uses integrated measuring systems to align the panel for the cut. Advanced models, like those from Striebig, feature digital readouts, laser guides, or fully automated positioning systems to ensure perfect alignment down to a fraction of a millimetre.

- Making the Cut: The saw head, which is mounted on a robust carriage, moves either vertically or horizontally along precision-engineered rails to perform the cut. The panel itself remains static, which is a key safety and accuracy feature. The saw blade, with a specified blade diameter or saw blade diameter, is crucial for cutting performance and compatibility with different materials. The saw beam can be locked for horizontal cuts or moved up and down for vertical cuts. For even more precise, chip-free cuts, an optional scoring unit can be used.

- Adjusting Feed Speed: On more advanced models, the feed speed of the saw head can be adjusted to suit the material being cut. For delicate materials like acrylics or laminates, a slower, controlled speed prevents chipping. For standard MDF or plywood, a faster speed can be used to maximise productivity. Fully automated systems can even set the optimal speed automatically.

- Efficient Dust Extraction: A crucial feature of any professional vertical panel saw is its integrated dust extraction system. As the saw cuts, a shroud around the blade captures dust and debris at the source, connecting to a central dust collection system. This keeps the workshop cleaner, improves air quality for the operator, and ensures the cutting line remains visible.

Key Advantages of a Vertical Panel Saw

Choosing a vertical panel saw offers a multitude of benefits that directly impact a workshop’s bottom line, safety record, and overall efficiency. One of the major advantages is its space-saving design, which requires minimal floor space and is ideal for workshops with limited space.

Vertical panel saws feature a generous cutting range, allowing for the processing of large panels with ease. The machine is designed with distinct areas for material handling and cutting, ensuring smooth workflow and organisation.

A key feature of these machines is their vertical cutting capability, which provides precise and efficient results. The user-friendly design makes operation easy, even for those new to panel saws.

Overall, vertical panel saws are highly suitable for panel cutting applications, offering accuracy, efficiency, and space-saving benefits for any workshop.

Unmatched Space Efficiency

For many workshops, floor space is the most valuable commodity. A traditional sliding table saw requires a large footprint, not only for the machine itself but also for the travel of the sliding table and the area needed to manoeuvre large sheets.

A vertical panel saw, by contrast, features a highly space-saving design, often requiring as little as 5 m² of floor space, making it ideal for workshops with limited space.

The front-to-back depth of the Striebig range is consistent and minimal, allowing you to place it against a wall and reclaim valuable workshop areas for other processes.

Superior Precision and Accuracy

Striebig vertical panel saws are world-renowned for their accuracy, offering cutting precision down to 0.1 mm. This level of precision produces glue-ready edges straight off the saw, eliminating the need for secondary finishing processes and saving valuable time.

For even greater precision and chip-free cuts, an optional scoring unit can be added.

The accuracy is further enhanced by the saw blade, with the blade diameter and saw blade diameter being a key factor in achieving precise results. The maximum cutting depth is 60 mm, making these saws suitable for a wide range of materials.

This accuracy is a result of Striebig’s commitment to engineering excellence. The rigid, self-supporting welded frame ensures absolute parallelism between the guide rails and supports, guaranteeing long-term stability and consistent cut quality for years to come.

Enhanced Operator Safety

Safety is paramount in any workshop. The design of a vertical panel saw inherently reduces many of the risks associated with table saws. Because the panel remains static during the cut and the saw head is enclosed and moves along a controlled path, the risk of dangerous kickback is virtually eliminated.

Furthermore, Striebig saws incorporate numerous safety interlocks; for example, the saw will not operate if guards are not correctly in place. From an ergonomic perspective, loading panels vertically is less strenuous than lifting them onto a table saw, reducing operator fatigue and the risk of injury.

Exceptional Versatility

A modern workshop needs machinery that can handle diverse materials. A vertical panel saw is not limited to just wood-based panels like MDF, plywood, or chipboard.

The robust construction and adjustable cutting parameters of Striebig saws make them perfectly suited for panel cutting across a wide range of materials, including plastics, acrylics, aluminium composite materials (ACM), laminated boards, and other non-wood composites.

The machine’s generous cutting range accommodates different panel sizes, enhancing its capacity for various workshop needs. Its design features distinct areas for material handling and cutting, optimising workflow and safety.

Some advanced models also support four-sided trimming without needing to rotate the panel, a feature that dramatically increases efficiency.

Increased Productivity and Automation

For businesses looking to scale their operations, automation is key. The Striebig range offers various levels of automation, from the manual COMPACT to the fully automated CONTROL and 4D models.

Features like automatic positioning, programmable cut cycles, and digital measuring systems make operation easy and efficient for the user by reducing setup times, minimising operator error, and ensuring perfect repeatability.

For high-volume or repetitive work, this translates into significant time savings and a more streamlined production workflow.

Excellent Cost Efficiency

Investing in a vertical panel saw delivers a strong return on investment.

Lower Labour Costs: Many models can be safely and efficiently operated by a single person, even when handling full-sized 8×4 sheets. This frees up personnel for other tasks, directly reducing labour costs.

Less Material Waste: The extreme accuracy of the cuts means fewer mistakes and rejected parts, significantly reducing material waste and scrap costs.

Long Service Life: Striebig saws are built in Switzerland to an exceptionally high standard. Their durable construction ensures a long and reliable service life, making them a sound long-term investment.

Vertical Panel Saw vs. Sliding Table Saw: Why Choose Vertical?

While sliding table saws have their place, a vertical panel saw, often referred to as a wall saw, often proves to be the superior choice, especially for panel cutting and processing.

Vertical panel saws offer a range of benefits over sliding table saws, such as:

- Space: A sliding table saw can require two to three times more operational floor space than a vertical panel saw to cut the same size sheet. The space-saving design of vertical panel saws makes them ideal for workshops with limited space.

- Material Handling: With a vertical panel saw, the sheet stays still, and the saw moves. This is ergonomically superior and safer than pushing a large, heavy panel across a table saw.

- Cutting Range: Vertical panel saws offer a generous cutting range, allowing efficient processing of large panels, while sliding table saws may be limited by their table size.

- Vertical Cutting: Vertical panel saws excel at vertical cutting, providing precise and consistent results for a variety of materials.

- Cut Quality Consistency: The automated feed speed and digital stop systems on a vertical saw deliver highly repeatable cuts every time, something that is harder to achieve manually on a table saw.

- Safety: The enclosed blade and controlled movement of a vertical panel saw present a far lower risk of operator injury compared to the exposed blade and manual feeding on a table saw.

- Return on Investment: While a sliding table saw might have a lower initial purchase price, the long-term ROI of a vertical panel saw is often higher when you factor in savings on space, labour, material waste, and improved productivity. Panel cutting efficiency and space-saving benefits further enhance the value of a vertical panel saw.

Why TM Machinery Recommends Striebig Vertical Panel Saws

As the exclusive UK distributor, TM Machinery has an intimate understanding of the Striebig range and a deep appreciation for its Swiss-engineered quality. Striebig has specialised exclusively in producing vertical panel saws for over 50 years, making them the undisputed market leaders.

Other reputable brands in the vertical panel saw market, such as Holzher, are also known for their engineering quality and precision. Striebig has been manufacturing vertical panel saws for more than 50 years, demonstrating its long-standing expertise and commitment to innovation year after year.

When considering different models, each Striebig machine is identified by its specific type, allowing buyers to select the right type for their needs.

A Model for Every Need

Striebig offers a comprehensive range to suit any application and budget:

- COMPACT (type 520, year introduced: 2005): The entry-level model, available in manual or automatic versions, offering economy and flexibility.

- STANDARD / STANDARD S (type 622, year introduced: 1998): The versatile workhorse, ideal for businesses of all sizes, with an extensive range of options and accessories available on the ‘S’ model.

- EVOLUTION (type 721, year introduced: 2007): Features an intuitive touch-screen control and numerous automated functions, making it one of the most efficient manually operated saws available.

- CONTROL (type 922, year introduced: 2010): A fully automated saw offering a high-production panel sizing solution with an optimised cutting process.

- 4D (type 1210, year introduced: 2015): The pinnacle of vertical panel saw technology, capable of optimising and cutting a full-sized panel without the operator needing to re-handle it after loading.

Uncompromising Service and Support

TM Machinery has been a trusted name in woodworking machinery since 1983, with over 40 years of experience in the industry. Our partnership with Striebig means customers receive:

- Expert Guidance: Our team helps you select the right model and specifications for your unique business needs.

- Reliable After-Sales Support: We offer comprehensive servicing, training, and a ready supply of genuine spare parts to keep your machine running perfectly. Customers can easily request service or support at any time.

- Showroom Access: At our Leicester location, you can see working Striebig models—including the COMPACT, STANDARD S, and CONTROL—to experience their quality first-hand.

- Proven Longevity: Our engineers service Striebig saws that are decades old, a testament to their incredible durability and build quality.

Saw Beam Maintenance: Keeping Your Vertical Panel Saw in Top Condition

Maintaining the saw beam of your vertical panel saw is essential for achieving maximum cutting precision and ensuring the long-term reliability of your machinery.

The saw beam serves as the backbone of your panel saw’s cutting system, it is responsible for guiding the saw head smoothly and accurately along both vertical and horizontal axes.

When properly maintained, the saw beam delivers consistently precise cuts, reduces the risk of misalignment, and helps you avoid costly downtime.

Why Saw Beam Maintenance Matters

A clean, well-lubricated, and correctly aligned saw beam is crucial for maintaining the high standards of precision that Striebig and other leading vertical panel saws are recognised for.

Over time, dust, resin, and debris can accumulate on the beam and its guide rails, potentially causing friction, uneven movement, or even minor deflections that compromise cut quality.

Regular maintenance not only preserves the integrity of the saw beam but also enhances the life of your entire panel saw.

Essential Saw Beam Maintenance Tips

Daily Cleaning: After each day’s utilisation, wipe down the saw beam and guide rails with a clean, dry cloth to remove dust and panel residue. This simple step helps prevent build-up that can affect the smooth travel of the saw head.

Lubrication: It is essential to periodically apply a manufacturer-approved lubricant to the moving parts of the saw beam, including bearings and guideways. Proper lubrication ensures effortless movement and reduces wear on critical components.

Inspection: It is crucial to routinely check the saw beam for signs of wear, damage, or misalignment. This includes looking for any unusual noises, resistance, or play in the saw head as it moves along the beam. Early detection of issues allows for prompt correction and avoids more serious problems down the line.

Alignment Checks: Utilising precision measuring tools to verify that the saw beam remains perfectly parallel to the panel supports and the cutting path is vital. Even minor misalignments can impact the accuracy of your cuts, so regular checks are essential for maintaining maximum cutting precision.

Follow Manufacturer Guidelines: It is crucial to always refer to your panel saw’s manual or TM Machinery’s recommendations for specific maintenance intervals and approved products. Utilising the correct cleaning agents and lubricants will help you avoid damage and keep your vertical panel saw performing at its optimum level.

By making saw beam maintenance a regular part of your workshop routine, you will protect your investment, ensure every cut meets your exacting standards, and enjoy the full benefits of your vertical panel saw’s advanced engineering.

Consistent care of the saw beam is the key to achieving maximum cutting precision, day after day.

Typical Applications for Vertical Panel Saws

The versatility of a Striebig vertical panel saw makes it an invaluable asset across numerous industries, with panel cutting being a core application in sectors that require efficient and precise processing of large sheet materials.

Furniture & Joinery: For accurately cutting large MDF, plywood, or laminated sheets for cabinets, kitchens, wardrobes, and doors, the key areas where panel cutting is essential.

Shop Fitting & Retail Display: Precision cutting of laminated boards, acrylics, and decorative panels for merchandising units and store interiors, serving areas such as retail environments and commercial spaces.

Plastics & Composites Fabrication: Ideal for industries working with plastics, ACM (aluminium composite material), and other non-wood panels for signage, cladding, and industrial components, all of which are important areas for specialised panel cutting.

Construction: For quick and accurate sizing of wall panels, insulation boards, and other building materials on or off-site, covering areas like construction zones and building sites.

High-Production Environments: Automated models like the CONTROL and 4D are perfect for factories and workshops that require high-volume, repetitive, and consistent panel cutting across multiple production areas.

Take the Next Step with TM Machinery

Choosing the right machinery is an investment in your business’s future. A Striebig vertical panel saw from TM Machinery offers a path to greater efficiency, higher quality, and improved profitability.

The best way to appreciate the quality of a Striebig is to see it in action. Book a demonstration at our Leicester showroom location.

Contact Us Today

Contact us for a free, no-obligation consultation. Our team will help you identify the perfect vertical panel saw to match your workflow and budget.

Fill out our contact form or call us today to request a personalised quote for a machine tailored to your exact requirements. All prices are excluding VAT.

Frequently Asked Questions

Is a vertical panel saw better than a table saw for cutting large panels?

Yes, for large sheet materials, a vertical panel saw offers superior space efficiency, safer and easier manual handling, and consistently higher precision than a sliding table saw.

How accurate are Striebig vertical panel saws?

They are exceptionally accurate. Striebig machines can cut with a precision of 0.1 mm, delivering high-quality, glue-ready edges that require no further processing.

What materials can a vertical panel saw cut?

Beyond all types of wood-based panels, Striebig vertical panel saws are designed to effectively cut plastics, composite panels, ACM, laminated boards, acrylics, and a wide range of other sheet materials.

How can I search for the right vertical panel saw for my needs?

You can easily search for the ideal vertical panel saw by using our website’s search function to filter models based on your requirements. You can also sign up to receive new offers and updates automatically via email, making your search process more convenient and efficient.

How do I request more information or a quote?

To request more information or a quote, simply fill out our online contact form. Our team will respond promptly with the details you need. You can request updates, new offers, or terminate your request at any time for maximum flexibility.