Do you find dust extraction terminology confusing?

The sheer volume of terminology relating to dust extraction can feel never-ending and, in many cases, largely unnecessary. That’s why we have picked a few key terms that cover the fundamentals and will make those conversations around your dust extraction needs easier to have.

That’s where we come in. At TM Machinery, we’re here to simplify the process for you and help you find the best solutions for your individual needs, whether you’re running a small workshop or a large-scale furniture production factory.

Dust extraction – what do I need to know?

As a legal requirement so there’s no skirting around the language. Of course, with the right supplier you don’t need to be an expert in dust extraction technology. You present the problem, and they should come up with the best solution for your specific needs, whether the smaller workshop or large-scale furniture production factory. However, understanding the basics of dust extraction terminology can help those conversations flow and give you confidence in making the right choice. This is why we have compiled a list of some of those keywords and expressions. It’s not exhaustive, but it’s a good starting point.

Automatic Dust Discharge

Minimising the need for manual emptying of dust containers saves time and reduces the risk of secondary dust exposure and combustion. Dust extraction systems with automatic discharge remove the dust captured in the filters, depositing it safely into movable containers.

Centralised Dust Extraction System

With a network of ducting that collects dust from various points and returns to one dust extraction unit, a centralised system is commonly seen in large woodworking and manufacturing factories that have many machines in a large area. However, compact extraction systems, such as the AL-KO Eco-JET and Power Unit ranges are now available to do the same job for smaller workshops. These can sit either outside or within the workshop and offer adaptable design, useful optional features and high extraction rates that make them suitable for multiple machines.

Compressed air cleaning systems

Compressed air is commonly used to clean filters in dust extraction systems, with methods ranging from continuous airflow to jet pulse systems. However, the ALKO OPTI JET® Filter Cleaning system stands out with its advanced design, using precisely timed and automatically adjusted air pulses to provide highly efficient and optimized filter cleaning.

Pre-Separator

A chamber to slow down the incoming air or a cyclone system that uses centrifugal force to remove larger particles before the air reaches the main filter, reducing wear and tear on your dust extractor’s impeller fan and filter. These can be separate to the dust extraction unit, but the most advanced dust extraction units feature integrated pre-separators, minimising the footprint of the dust extraction unit with a streamlined and space-saving design.

Decentralised Dust extraction unit

Point-of-use dust extraction units for individual woodworking machines or workplaces, such as a sanding table, are often referred to as decentralised systems or units. Locating your LEV system close to the processing machinery is efficient and adaptable, reducing the amount of ducting required and increasing flexibility for changing workflows.

Explosion panels

Dust is highly combustible and mitigating against the risk and impact of explosions is a legal requirement. For a dust extraction system inside a workshop, this often means an explosion relief panel and vent, typically redirecting the explosion pressure outside the workshop to a safe place. However, with the latest high-tech designs, the best de-centralised dust extraction systems will be explosion tested and can be safely housed indoors, fully complying with BS EN 16770 legislation covering the design and specification of such systems.

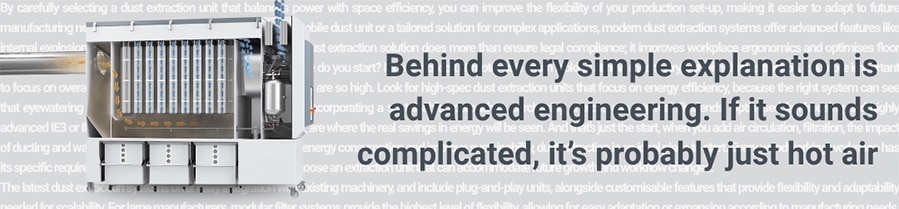

Impeller fan

An impeller sucks or pulls air, in contrast to a propeller which pushes air. Traditionally positioned before the filter, the latest and most efficient units place the impeller behind the filer in a more aerodynamic design allowing it to operate exclusively with clean air to increase efficiency, filtration, and reduce maintenance.

M-Class filters

With extremely high levels of fine particle extraction, M-Class filters are the legal requirement for anyone creating mixed wood dust. For those working with softwood, M-Class are still recommended, ensuring the safest working environment and building flexibility for future manufacturing plans. Wood dust is highly combustible, so filters made of antistatic polyester needle-felt material are beneficial.

Parallel Fans

For large-scale furniture manufacturers and workshops that generate a high volume of dust, duo version extraction units will significantly increase airflow and extraction capacity. Automatically adjusting and maintaining consistently high-volume airflow, these parallel fan systems are particularly beneficial where variable workloads and long duct runs can create pressure drop issues.

Pressure Drop

The difference in static pressure between the inlet and outlet of the dust extraction system. Air pressure decreases when it comes across obstacles, like badly designed ducting and poorly maintained filters. The correct ducting size, strategic filter bends, high-quality filter systems with automatic compressed air cleaning, all contribute to low-pressure drops, ensuring your dust extraction system works efficiently and safely.

Static Pressure

A dust extraction system needs to move large amounts of air at high speed, and everything air comes against, from ducting to filters and flexible hoses, creates resistance. The higher the resistance, the more static pressure the dust unit must generate to overcome this. This requires more power and expense and can lead to reduced performance, higher maintenance costs and higher risk of combustion. Getting the ducting design and filter selection right reduces the effort needed to move the air, requiring a less powerful dust unit and saving money.

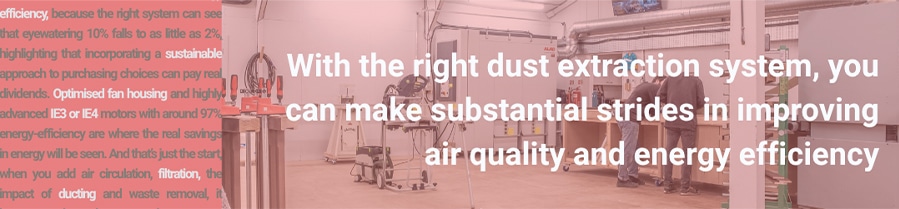

Simplifying Dust Extraction for You

In the woodworking industry, staying informed about the latest advancements in dust extraction technology is key to improving your workspace, but that doesn’t mean that you should be bamboozled with overly complicated terminology. At TM Machinery, we’re here to simplify the process for you. We can help find the best solutions to improve air quality and safety in your workshop and we won’t need to use complicated terminology to do it.

Ready to take the next step and find the best dust extraction solution?

With over 40 years of experience in the woodworking industry, we are experts in dust extraction, with the most efficient and flexible systems in the market. Get in touch today and let’s talk through how to achieve cleaner air, a safer environment, make the most of user-friendly automation, and ensure future flexibility – all in language that makes sense.