Even the Best Equipment Can’t Prevent Human Error

Striebig Vertical Panel Saws are engineered for reliability, precision, and operator safety. With a system designed for fast, straightforward blade changes, they help keep your production running smoothly — with minimal downtime.

But a recent call-out by one of our clients was a powerful reminder: even with the best equipment, human error can still cause problems.

After a routine blade change, an operator at one of their branches reported cutting issues. When our engineers arrived, they found that the guard wasn’t retracting — and the blade wasn’t visible.

The cause? The blade was loose, with the flange and locking screw left inside the housing. It appears the blade had been removed, left loose, and the door simply closed.

This was human error, and an avoidable oversight.

Had those loose components come into contact with the high-speed spindle, the impact could have caused significant damage to the machine — and possible injury to employees.

Thankfully, on this occasion, there was no damage to the casing, riving knife, scoring saw, or guard — and no injury. But had it gone unnoticed, the consequences could have been far more serious.

This Wasn’t a Machine Fault — It Was a Missed Step

The Striebig range of saws are designed for exceptional safety. But like any machine, they rely on safe use. A rushed reassembly or a skipped check can turn a routine task into a serious risk.

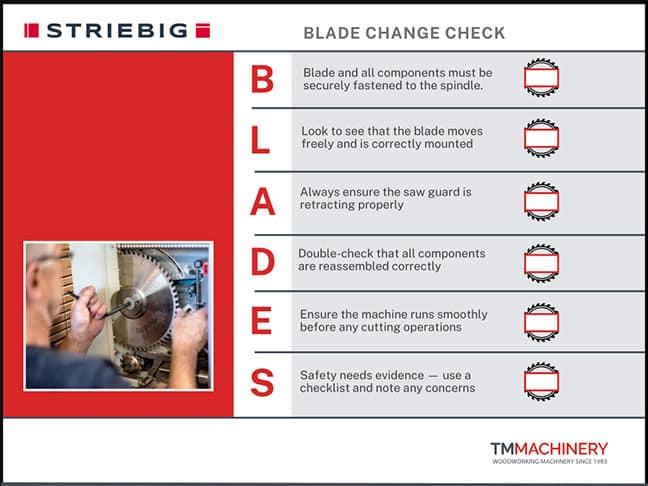

This is why we always recommend that blade changes are followed by a consistent process of pre-operation safety checks to help prevent avoidable risks — and backed up with regular servicing and safety checks.

You can download our blade change checklist here – Blade Change Check.

Our Service and Maintenance Support

While quick pre-operation checks are essential, the safest option is to schedule regular vertical panel saw servicing — and that’s where our TM service team comes in.

Our engineers are Striebig-trained and keep up to date with ongoing training courses and technical briefings in Switzerland. Whether you’re running a fully automated model or making the most of the Striebig build quality with an older manually operated machine, we support our clients with expert, friendly servicing and preventative maintenance to keep operations running smoothly.

We work with woodworking shops, furniture manufacturers, joinery specialists, and any business that is reliant on accurate cutting for panel processing across the UK, with a back-office team ready to source parts, provide technical advice, and support every aspect of your production.

With the right safety protocols in place and regular servicing from our team, we can work together to track advisories and flag potential issues before they escalate — keeping downtime to a minimum and your team working safely.

A Small Oversight. A Fast Response. A Useful Reminder.

In this case, our client was back up and running quickly, and safety protocols were immediately reinforced across their business.

At TM, we’re here to support woodworking professionals and furniture manufacturers not just with machines, but with the knowledge, servicing, and systems that keep production lines performing at their best.

Contact Us Today

If you’re unsure after a blade change — or want to book a visit — talk to our team.