TM Machinery’s guide to Striebig Vertical Panel Saws

A vertical panel saw is becoming increasingly popular as an alternative to the more traditional sliding table panel saw. Being vertical, the panel saw is great when lack of space is an issue in a workshop. In fact, vertical panel saws, also known as wall saws, offer considerable benefits which we will look at in more detail in this article.

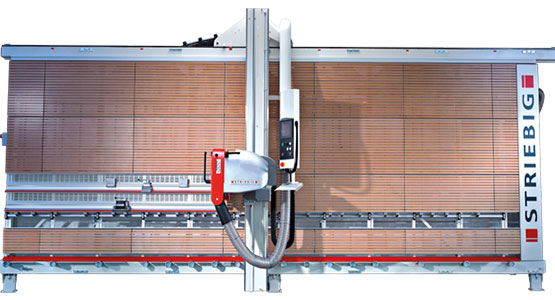

TM Machinery are the exclusive UK distributor of Striebig Vertical Panel Saws. The vertical panel saw range from Striebig of Switzerland is well known throughout the panel sizing industry, with a reputation for accuracy and longevity.

Striebig only produce vertical panel saws and have been doing so for over 50 years, with huge success in the wood, plastics and ACM markets. The quality of construction, innovative technology and accuracy of their machines, have made Striebig the undisputed market leaders. To discuss your individual requirements please contact a member of our team today.

What is a vertical panel saw?

With a vertical panel saw the material that is being cut is supported in an upright position whilst being cut. The panel remains static throughout and the saw head and saw beam travel vertically or horizontally to perform the cut.

The design of this type of saw means that it can sit up against a wall, hence being frequently called a wall saw.

It’s not just wood based panels that can be cut, vertical panel saws are ideal for cutting plastics and composites too.

The Striebig Panel Saw Range

Striebig offer 6 different vertical panel saws within their range, all available exclusively from TM Machinery. Each saw has a wide range of options and features to choose from meaning you can choose the right saw for your specific requirements.

- Striebig COMPACT – entry level manual and automatic saw, economical and flexible.

- Striebig STANDARD – the ideal saw for businesses of all sizes with a wide choice of cutting ranges.

- Striebig STANDARD S – takes the STANDARD to the next level with 20 additional options and accessories to choose from.

- Striebig EVOLUTION – numerous automated functions making it the most efficient manually operated saw available.

- Striebig CONTROL – fully automated saw with a high production panel sizing solution.

- Striebig 4D – optimise and cut a full-sized panel without the operator needing to re-handle it once it has been loaded on to the machine’s bed.

Technical advantages of a vertical panel saw

The vertical panel saw range from Striebig offers close dimensional adherence matched by a cutting precision of 1/10 mm and finishing-cut quality. Cutting depth is 60mm on the COMPACT and 80mm on the other saws.

Striebig saws can offer the technology required for trimming on four sides without the need for turning. Automatic feed speeds can also be adjusted to suit the material on most vertical systems.

Size and Capacity of vertical wall saws

Striebig offer a wide range of sizes for their extensive vertical panel saw range to suit all types of work.

For example, the Striebig COMPACT vertical panel saw comes in nine different sizes to suit all panel types however big or small. Cutting ranges are from 3100 x 1644mm up to 5350 x 2200mm.

All saws offer the advantage of having low space requirements as the front to back depths of the saws in the Striebig range do not vary making them the perfect choice when space is an issue.

Cutting Quality of a Vertical Panel Saw

Cutting Quality of a Vertical Panel Saw

The Striebig saw frame is self-supporting, welded and heavily braced. It provides absolute parallelism between the upper guide rail, the central support and roller support so as to ensure precise cutting over many years and a long working life.

The precision cuts you get on saws like the Striebig STANDARD vertical panel saw ensure glue-ready edges without any reworking giving you long lasting value and security of investment.

One Person Control

With regard to operating personnel, the differences between horizontal and vertical saws are apparent.

A vertical panel saw such as a Striebig CONTROL vertical panel saw can be operated by one person with simple handling equipment even when large-sized panels are involved.

In comparison, horizontal machines require two operators when positioning large-sized panels.

Ease of Use

Striebig’s innovative and user-friendly “touch and saw” operating system on the Striebig EVOLUTION vertical panel saw delivers easy and convenient machine control through a touch screen panel that operates all of the machine’s functions.

The new 12-inch colour screen gives visual images of all operations. It incorporates error detection with self-explanatory symbols to guide the operator through the menu, with operating errors reduced to the greatest possible extent.

In Summary

Vertical panel saws are an ideal solution for companies that require fast, accurate and efficient panel sizing. They are easy to use and fast to set up. There are excellent safety features meaning that operators can be trained faster.

There are major cost benefits too, both in terms of space saving in a workshop and manpower with only one operator needed. Vertical panel saws can also increase production efficiencies and guarantee a consistently accurate output.

Contact TM Machinery Today

For more information on the wide range of Striebig Vertical Panel Saws available exclusively from TM Machinery please contact us today.