It’s a question that is commonly asked: should I buy a vertical panel saw or sliding table saw? Here, we explore why a Striebig vertical panel saw might be a worthy option for you…

When discussing the difference between a vertical panel saw and sliding table saw, the machine’s space requirements are an obvious starting point. The space-saving credentials of a vertical panel saw have been well documented over the years and have often been a deciding factor for many businesses looking to invest in a new machine.

After all, even when working with jumbo sheets (2800 x 2070mm), a vertical panel saw requires just 7sqmt of working space – a third of the space required by an equivalent sliding panel saw. However, the advantages don’t stop there.

Striebig Vertical Panel Saw

The beauty of a Striebig vertical panel saw is its moving saw head. This offers the operator a wealth of benefits, including a reduction in material handling. Even when you’re performing multiple cuts, you only need to handle a full sheet when it is initially loaded onto the machine and, due to its vertical design, the board’s edge simply needs to be put directly onto the datum before the cutting process can begin. This removes the risk of the board being positioned incorrectly and ultimately, speeds up the cutting cycle.

The beauty of a Striebig vertical panel saw is its moving saw head. This offers the operator a wealth of benefits, including a reduction in material handling. Even when you’re performing multiple cuts, you only need to handle a full sheet when it is initially loaded onto the machine and, due to its vertical design, the board’s edge simply needs to be put directly onto the datum before the cutting process can begin. This removes the risk of the board being positioned incorrectly and ultimately, speeds up the cutting cycle.

On a sliding table saw, the blade remains stationary and relies on the board being manually positioned and fed through the blade. When cutting a jumbo sheet, it requires two people to operate the machine due to the size and weight of the sheet and a large workspace either side of the blade to handle the material safely. The level of accuracy on each cut is dependent on the operator positing the board correctly against the fence and keeping it in position during the cutting process. This lends itself to inconsistent cuts and material wastage.

Automated Cut Cycle

Then there’s a question of cut quality. Both saw types require a good quality, vibration-free saw blade and the right blade and feed speeds. Regardless of a sliding table saw’s build quality or price-point, the feed speed can only be controlled via the operator. This requires a certain level of skill, material knowledge and concentration. Vertical panel saw models in the Striebig range can offer an automated cut cycle with accurately controlled feed speeds, which reduces operator-error and guarantees a high-quality cut every time, even when cutting challenging materials like thick plastic or working with exceptionally large sheets over six metres long.

With many sliding table saws, automation is limited to the positioning of stops. With a vertical panel saw, the level of automation available is far superior, removing potential operator error and accuracy issues. It also lessens the skills required to use the saw effectively.

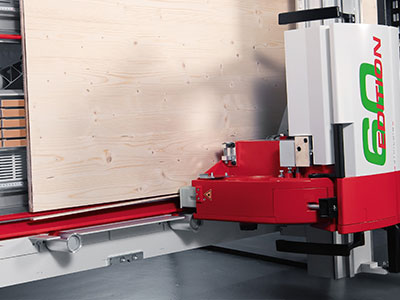

Striebig’s models feature a wealth of automated features, including automatic positioning digital measuring stops, fully automated cut cycles, laser guided indicators, pneumatically-braked support rollers and automatic trimming. The new Edition 60 also comes with an integrated panel-lowering device that positions each panel automatically, eliminating the need to turn the sheet by hand during the cutting process entirely.

Striebig’s models feature a wealth of automated features, including automatic positioning digital measuring stops, fully automated cut cycles, laser guided indicators, pneumatically-braked support rollers and automatic trimming. The new Edition 60 also comes with an integrated panel-lowering device that positions each panel automatically, eliminating the need to turn the sheet by hand during the cutting process entirely.

Intelligent features such as this can also be teamed with optimisation software that can be built into the machine or retro-fitted at a later day. It can also be partnered with stock and waste management software and CAD/CAM software programmes to streamline production and benefit from industry 4.0 manufacturing processes.

Panel Saw Safety

Operator safety is always of paramount importance to any saw manufacturer but, as the statistics show, you are less likely to suffer injury on a vertical panel saw. On a sliding table saw, the blade is always exposed, whereas a on a vertical panel saw, it is completely contained within its housing during operation and run-down. On a Striebig saw, you also can’t turn the saw on if the housing is open or unlocked. In addition to this, a vertical panel saw is also less labour intensive – it’s easier to move the saw head on a Striebig than it is to manually feed large sheets through a table saw – making it an exceptionally safe and effective workhorse.

Matt Pearce, Managing Director of TM Machinery says: “The space saving of a vertical panel saw should never be overlooked but there are so many more benefits a Striebig can offer. Comparable in price to a sliding table saw but offering a different approach to cutting sheets to size, a Striebig saw removes many of the issues associated with cutting large panels, guaranteeing accuracy within 0.1mm on every cut. On top of this, the finish of the cut means the board can be put straight through an edgebander without further machining or hand-finishing, offering the user a wealth of possibilities when using panels, composites, plastics and metals. To see the results for yourself, book a demonstration at our Leicester showroom and explore the full capabilities of a Striebig vertical panel saw.”

For more information please call +44 (0)116 271 7155 or email sales@tmservices.co.uk.

For the latest news, follow TM Machinery on Twitter: https://twitter.com/tm_machinery.